3D Printing Process – One-Stop Service Solution

Modeling

Use modeling software to generate digital models. For example, use professional modeling software (such as 3DMax, CAD) to build a three-dimensional model. Ensure that the model’s accuracy and complexity are compatible with the characteristics of light-curing technology.

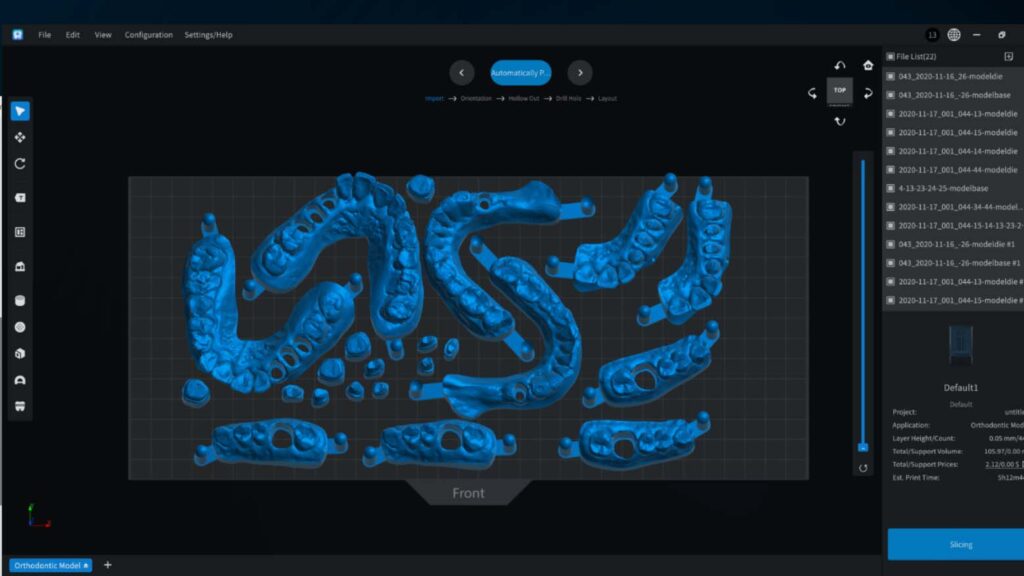

Slice processing

Convert the digital model file into an STL file and import it into the slicing software for processing. Decompose the model into two-dimensional cross-section data, plan the scanning path, and optimize the process parameters to ensure the curing accuracy of each layer.

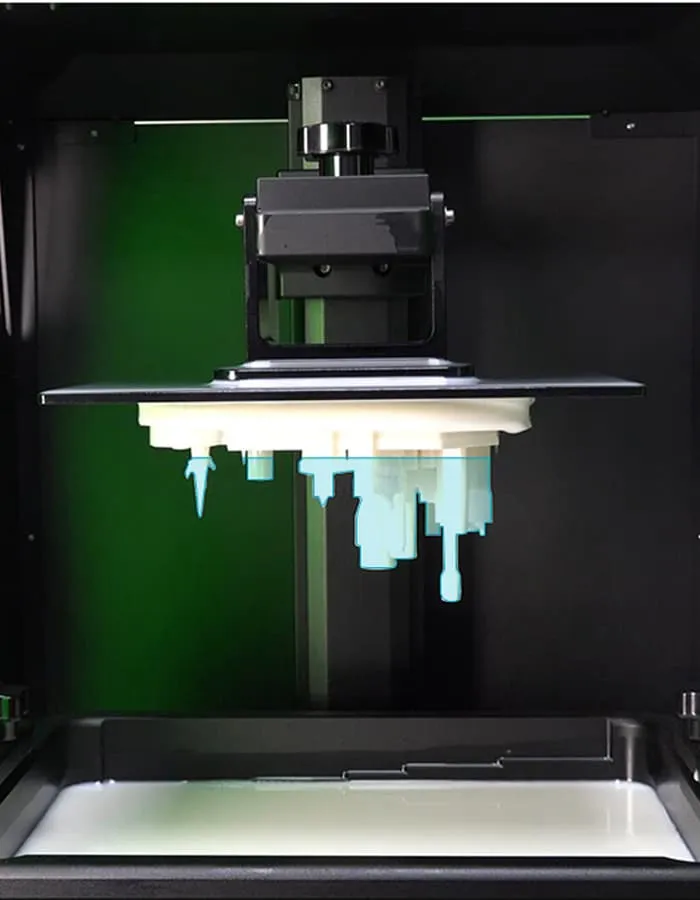

Printer Print

The model slice file is imported into the light-curing 3D printer for intelligent recognition and printing, and is cured layer by layer by ultraviolet laser beam; the resin is irradiated layer by layer according to the slicing instructions to realize three-dimensional solid construction.

Remove supports

After removing the model from the 3D printer, trimming support structures and sanding it down require carefully planned disassembly steps, experienced operators, safety equipment, and a controlled work environment.

Post-processing

The printed model is processed and treated. After removing the support structure and polishing, the model is cleaned of residual resin, secondary cured to enhance strength, and the surface is post-polished and painted to complete the product.

Application Verification

The application of the model needs to be verified through various tests, such as dimensional accuracy inspection, surface quality inspection, mechanical component function testing, circuit testing of electronic components, and repeated verification of functional reliability on the prototype before final application.