Rigid Washable Resin 601

Name: 3D printing LCD/DLP rigid resin

Model:601

Color: multiple colour

Package:

Specification: 500g 1KG 10KG

Water washable toughphotosensitive resin

Product Description:

DYODE Washable Series 601 is a high-precision resin that can be cleaned directly with water (without soap and water). ABS-like nature, suitable for LED light source wavelength 365nm-405nm printer.

产品性能:

01 Low shrinkage

DAYOUDE photosensitive resin is specially designed to reduce volume shrinkage during the light curing process, ensuring high precision and surface finish of printed models, and is suitable for printing high precision assembly parts.

02 High-speed curing

The washable series resins allow for very fast layer curing times, layer thicknesses of 25-300 microns, easy release, and resistance to pull-off at speeds up to 1-2 seconds!

03 High precision

The cured model has a hardness of 81D, providing superior hardness and durability, making it ideal as a fixture or fixing device where high strength is required.

04 High strength

The washable series resins have excellent mechanical strength and even better impact resistance, and can be tapped directly.

05 High elongation degree

The material has excellent elongation at break, and the printed models are not easily pulled off, ensuring successful printing.

06 Good stability

Washable series resins do not stratify or change color after a long period of time, do not clump, and the printed models are durable.

Technical parameters:

Test Items | Test Results |

Viscosity | 180-260cps@25℃ |

Critical exposure energy | 7.5 mJ/cm2 |

Tensile strength | 36-52MPa |

Tensile modulus | 1,799-2,385MPa |

Elongation at break | 4-8% |

Notched impact strength | 30-40J/m |

Heat deflection temperature | 77℃ |

Shore hardness | 81D |

Printing parameters:

Printer Type | Test Items | Test Results |

LCD Printers | General layer (electronic ink screen) | 1-5 秒 |

General Layer (Color LCD) | 3-8 秒 | |

Ground floor | 15-50 秒 | |

DLP Printers | General Layer | 1-3 秒 |

Ground floor | 15-30 秒 | |

Note | When using a large size LCD screen to print large size models, it is recommended to try to control 4-5s to prevent the model from being pulled off too fast. | |

Note: The above values may vary in actual values depending on part geometry, print settings, temperature variations, secondary post-curing, etc. Therefore, the user must test the product before use to ensure that it will meet your end-use requirements for print performance. The above values are typical values and we do not agree to them as binding material specifications or warranties unless expressly agreed to in writing. Final results depend on the actual use of the user, and this table is for reference only.

01)Use fresh water

Under the faucet with water (without soapy water) directly clean, water pressure is not enough, you can use a toothbrush in the sink to assist in cleaning.

02)Use ultrasonic

Use ultrasonic machine to clean directly with water, the cleaning time is 30 seconds - 60 seconds.

Note: Washable resin 601# molding strength, can be tapped, can be polished, suitable for dental mold (non-casting), large size model printing.

Generally speaking, ordinary 3D printing resin products will inevitably have the problem of resin layering at the bottom. This is because some color paste contained in the opaque color resin will precipitate at the bottom after a long time, resulting in layered resin at the bottom. This not only affects the light transmission of the resin, but also directly affects the curing speed and accuracy of the model, which may lead to print failure in serious cases.

Although many suppliers recommend that customers shake the resin thoroughly before use so that it can be reused to remove the sediment from the bottom. However, if left for too long, the sediment may become thicker and difficult for customers to use. So our core technology is to solve this problem. No matter how long you leave it, there will be no sediment at the bottom, which will not affect the light transmission of the resin and make the best resin molding effect.

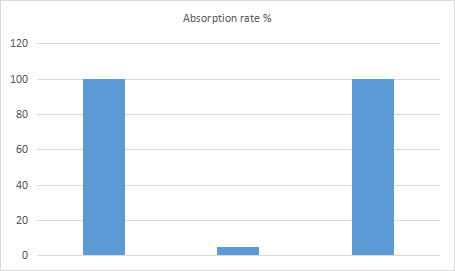

Biocompatibility testing | |||||

Sample | Receive Date | Test Results1 | Test Results2 | Average value | Cytotoxicity |

Morphology | MTT assay | ||||

601# | 0 | 0 | 0 | 无 | |

| Cytotoxicity: 0=none, 0-1=mild, 1-2=mild, 2-3=moderate, 3-4=severe | |||||

Sample | Receive Date | Surface area | Extraction media volume(ml) | Extraction temperature |

(cm2) | (℃) | |||

601# | 6 | 2 | 37 | |

Qualitative morphological classification

1. 601#

2. Negative control

3.Positive control

| MTT test grade | ||

Samples | Cytotoxicity(%) | Test Level |

601# | -0.09 | 0 |

Positive control | 93.87 | 4 |

Grade: <10%=0 10~30%=1 30~50%=2 50~70%=3 >70%=4 | ||

| Conclusion: This product does not contain toxic substances, has good biocompatibility and is not harmful to humans when used for dental purposes | ||

Suggested methods of sewage treatment

01、Use either the wastewater flocculant supplied by our company or precipitant and decolourant being sold on the market.According to the total weight of wastewater, add 1-5% and place for 12-24 hours. After solid-liquid separation, filter and classify treatment according to solid liquid classification.

02Directly use UV lamp to irradiate the waste water, solidify the resin liquid remaining in the waste water, then classify and dump the waste water after filtration.

Step 01 | Stir in |

Pour the waste water treatment agent into the waste water and stir for 2 minutes. | |

Step 02 | Water sampling |

According to the weight of the waste water.Add waste water treatment agent 1%-5%. | |

Step 03 | Let stand |

Let stand for 12-24 hours, it can be processed after solid-liquid separation The longer the placement time, the better the separation effect. |

Before use: Shake the liquid resin well before use, clean the resin tank and molding platform, and keep the bottom of the resin tank clear. Please wear gloves and a mask and keep the environment well ventilated.

When using: Unscrew the cap and add to the resin tank according to the equipment requirements, select the correct printing parameters and settings for printing.

After use: After printing, please use the supporting tools for post-processing, including blades, diagonal pliers, brushes, tweezers, containers, gloves, etc.; the residual liquid on the surface of the treated resin model can be rinsed directly with water.

A. Remove the printed model from the molding platform with a blade.

B. Cleaning process.

(1) rinse the model directly with water

(2) or ultrasonic cleaning for 1-3 minutes, then remove and evacuate the water.

(3) or use a toothbrush in the sink to assist in cleaning off the residual resin liquid on the surface of the model.

PS: Hot water works better in winter.

C. Use hair dryer to blow off the residual water on the surface of the model.

D. To ensure that the user gets the ideal material properties, secondary curing can be done (no need to cure in water ).

(1) secondary curing with high-pressure mercury lamp, LED lamp uniform irradiation.

Resin models can be cured at a distance of 5 cm from the light source, 10-15 seconds to cure, but thicker parts need more time

(2) or exposed to sunlight to dry (no more than 1 hour, can be adjusted by yourself).

PS: Material performance will vary depending on the molding equipment, post-curing methods and testing equipment.

E. It is forbidden to dump waste material at will, if it needs to be scrapped, please recycle the waste material locally according to [environmental regulations].

1. It is recommended that the resin be stored in a sealed room temperature environment, avoiding high temperature and sunlight.

2. The ambient temperature when printing, 18-35°C is recommended, lower temperature may affect the printing effect, the resin can be properly preheated before use (not more than 35°C).

3. If the resin has pigment stratification precipitation, it can be used after stirring or shaking.

4. Prohibit close to or long-term exposure to strong light sources such as high-powered high-pressure mercury lamps.

For safety information, please refer to the MSDS of this product. if you encounter any problems during use, please feel free to contact us.